Best quality Rotary Kiln Shell-Cooling Fan - Air lock feeding valve of the vertical mill – Fiars

Best quality Rotary Kiln Shell-Cooling Fan - Air lock feeding valve of the vertical mill – Fiars Detail:

Technical Characteristics

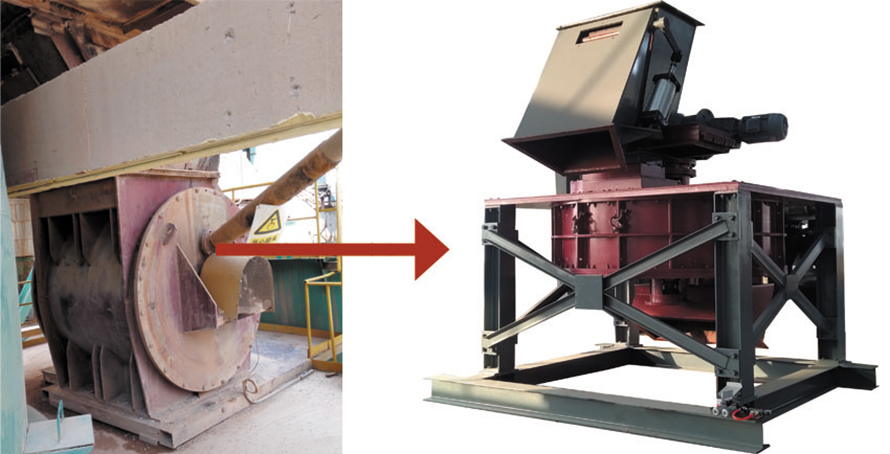

At present, the air lock feeding valve of the vertical mill usually uses the split wheel air lock (rotary feeder). But for the production line with wet material, it is easy to accumulate a large amount of raw material, resulting in the feeding difficulty of vertical mill, frequent shutdowns, seriously affecting the operation of vertical mill. And because the blade and cylinder often wear, resulting in heavy air leakage, increasing the load of the fan, and the gap increases will cause stuck, high operation and maintenance costs. After 3-5 years of operation, maintenance costs are equivalent to buying a new set of equipment.

The new air lock feeder of raw meal vertical mill is an equipment developed for the above defects, combined with the company’s years of experience in the application of cement production line equipment.

The equipment is smooth, no material stuck, good air lock effect, energy saving, stable and reliable. It is the optimal mode of vertical mill feeding mode after optimization and improvement.

Advantages of Equipment

a. The entire equipment only needs 3.5×2.4 meters of installation space, and the modification has little impact on the production;

b. Consistent with the size of the existing split wheel interface, it can be directly replaced, which needs small amount of installation work and short cycle;

c. It can effectively prevent the equipment from caking and stopping, which is conducive to improving the system operation rate and reducing the impact of insufficient raw material supply on the burning system;

d. It can effectively reduce the adhesion and harden of sticky materials, greatly reduce the labor intensity of manual cleaning;

e. Good air lock to improve the drying capacity of the system, improve the adaptability to grinding water, relieve the drop in output caused by wet material, reduce the impact on the full load production of the burning system.

The Benefits

a. It can save 8,000-16,000 USD maintenance cost per year.

b. A good air lock can improve the ability of selecting and separating fine powder inside the mill, so as to increase the output of the system by 5-10%, and further reduce the power consumption of grinding;

c. A good air lock can effectively reduce the operating load of vertical mill circulating fan and kiln tail exhaust fan, saving power up to 0.5 ~ 3kwh per ton of raw meal.

For benefit of the power saving, take 5000t/d clinker production line as an example: Raw meal mill circulating fan, burning system tail exhaust fan, reduce the start and stop of the mill, tons of raw material power consumption can be reduced 1kwh; According to the annual production of 1.56 million tons of clinker, need 2.43 million tons of raw material, will save 2.43 million KWH; According to the current power price of 0.09 USD per 1kwh, the annual power saving benefit reaches 230 million USD.

Product detail pictures:

Related Product Guide:

We now have a highly efficient crew to deal with inquiries from clients. Our intention is "100% shopper pleasure by our merchandise quality, price tag & our staff service" and take pleasure in a very good standing amongst purchasers. With quite a few factories, we can easily provide a wide vary of Best quality Rotary Kiln Shell-Cooling Fan - Air lock feeding valve of the vertical mill – Fiars , The product will supply to all over the world, such as: Colombia, Berlin, Paraguay, The company has perfect management system and after-sales service system. We devote ourselves to building a pioneer in the filter industry. Our factory is willing to cooperate with different customers domestic and overseas to gain better and better future.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.