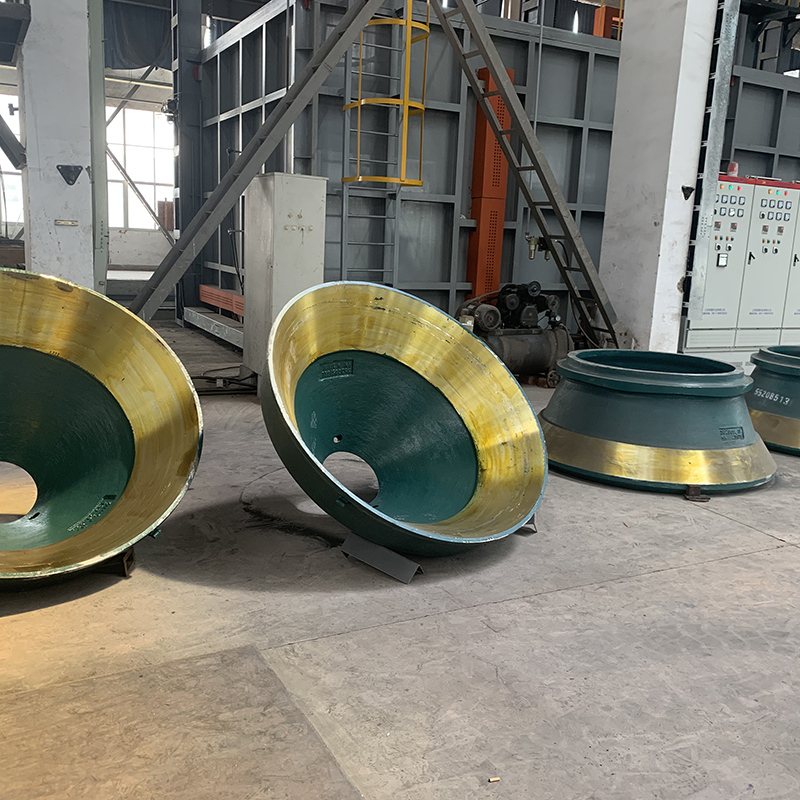

Factory Supply Wear And Tear Parts - Crusher and ball mill liner and diaphragm – Fiars

Factory Supply Wear And Tear Parts - Crusher and ball mill liner and diaphragm – Fiars Detail:

Technical Characteristics

a.Material:

The material of liner and diaphragm is medium alloy, which has strong wear resistance, good toughness and a wide range of applications. It can effectively prevent the impact of the material and the wear on the equipment shell, such as inside of ball mill body, crusher shell and etc., are all need to install the liner which made by this material, in order to improve the equipment operation rate and increase the output.

b. Advanced manufacturing process:

● Customized design: V method vacuum casting, mold open by computer which maximize guarantee the appearance size and accuracy of the product. The vacuum negative pressure increases the pressure during casting and improves the internal quality of the product to a certain extent. High, fine grinding and small grate is shaped with resin sand to ensure the accuracy of the grate gap size, without negative impact on the process performance of the equipment.

● Manufacturing process: Secondary annealing treatment and use the computer to accurately control the temperature, to achieve the purpose of grain refinement, further increased the toughness of the liner to prevent breakage.

● Quality Control: Smelting steel water shall be discharged after qualified spectral analysis; the test block for every furnace shall be heat treatment analysis, and the next process shall proceed after the test block is qualified.

c. Strict inspection:

● Flaw detection should be performed for each product to ensure that there are no air holes, sand holes, slag inclusions, cracks, deformation and other manufacturing defects.

● Each product is inspected prior to delivery, including material tests and physical performance tests to ensure functional performance and provide laboratory test sheets.

Performance index

Hardness: HRC45-52;

Impact toughness ≥60

Application

It is Widely used in the crusher and ball mill of mining, cement and metallurgy industry.

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Factory Supply Wear And Tear Parts - Crusher and ball mill liner and diaphragm – Fiars , The product will supply to all over the world, such as: Croatia, Guinea, Honduras, We are eager to cooperate with foreign companies which care much on the real quality, stable supply, strong capability and good service. We can offer the most competitive price with high quality,because we are much MORE PROFESSIONAL. You are welcomed to visit our company at any time.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.