Hot New Products Rotary Kiln Bearing Bushing - Cement mill roller press feeding device – Fiars

Hot New Products Rotary Kiln Bearing Bushing - Cement mill roller press feeding device – Fiars Detail:

Technical Characteristics

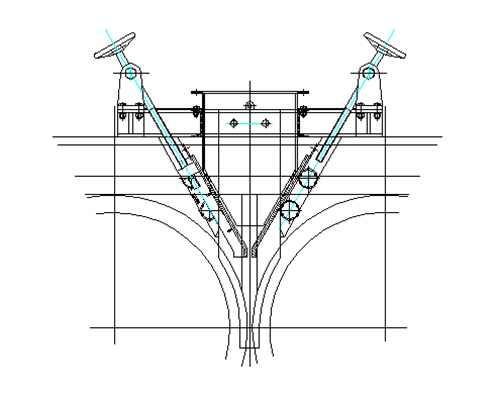

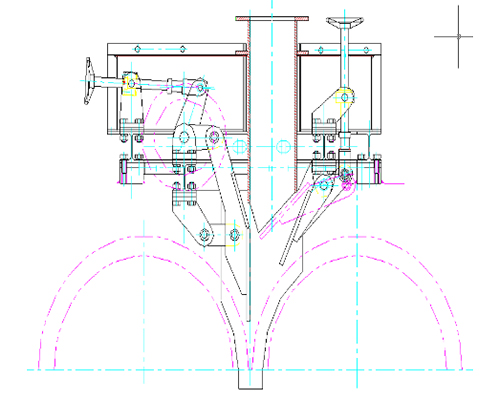

Roller press is an important equipment in cement production line. It can greatly increase the output of cement mill when used together with cement grinding. And because of its advantages such as simple structure, easy maintenance and low investment, it is also applied to the raw materials grinding more and more.

The feeding device of roller press mostly through heavy screw and artificial rotating hand wheel to adjust the flow of material into the roller press and adjust the amount of the material flow to the fixed roller and moving roller. Because most of the adjusting mechanism is inside the cover, the screw, articulated link is affected by the dust and its deformation and the site can’t make adjustment in time according to the change of the material and product, which causes the problems of roller press system such as material flushing, large dust, unstable operation, low efficiency of system work, large load of cycle hoist and so on.

The new feeding device of roller press is specially designed for the above defects, which greatly improves the serious wear and screw stuck, reduces the labor intensity of workers and reduces the maintenance cost.

Advantages of Equipment

a.The new type roller press feeding device is featured as reliable control, stable operation and the service life of key components has been greatly improved. It reduces the material edge leakage of roller press and so on;

b.The driving system of new feeding device of roller press adopts external type, and the lead screw is sealed by dust proof cloth so as to ensure that the lead screw will not be stuck or damaged by dust;

c.The new feeding device of the roller press adopts the bearing shaft to support and protect the whole flow regulating plate as much as maximum, and the central hinge connection is adopted between the drive mechanism and the regulating plate, so that no break of the regulating plate or the screw will occur;

d.The new feeding device of the roller press adopts a dual-display and high-precision angle transmitter for more accurate control;

e.The new feeding device of the roller press adopts an independent electronic control system, which is connected to the central control room. The operator can adjust the opening position for double or single side baffles according to the change of the working current of the roller press at any time to meet the requirements of the production process;

f. The baffle of the new feeding device of the roller press is gradually fully opened from closed, the material flow from small to large. The instantaneous impact on the roller press is eliminated, the vibration of the roller press when feeding is contained, and the wear and leakage of the roller surface are also controlled;

g.The new feeding device of the roller press ensures the synchronous action of the baffle on both sides, with higher accuracy, the materials are concentrated between the moving rollers and the fixed rollers, and the roller works more balanced.

Product detail pictures:

Related Product Guide:

We've got quite possibly the most state-of-the-art production gear, experienced and qualified engineers and workers, acknowledged top quality handle systems along with a friendly expert gross sales group pre/after-sales support for Hot New Products Rotary Kiln Bearing Bushing - Cement mill roller press feeding device – Fiars , The product will supply to all over the world, such as: Italy, St. Petersburg, Afghanistan, We'll supply much better products with diversified designs and expert services. We sincerely welcome friends from over the world to visit our company and cooperate with us on the basis of long-term and mutual benefits.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.