Hot Sale for Ball Mill Feed Silo - Roller sleeve of roller press – Fiars

Hot Sale for Ball Mill Feed Silo - Roller sleeve of roller press – Fiars Detail:

Technical Characteristics

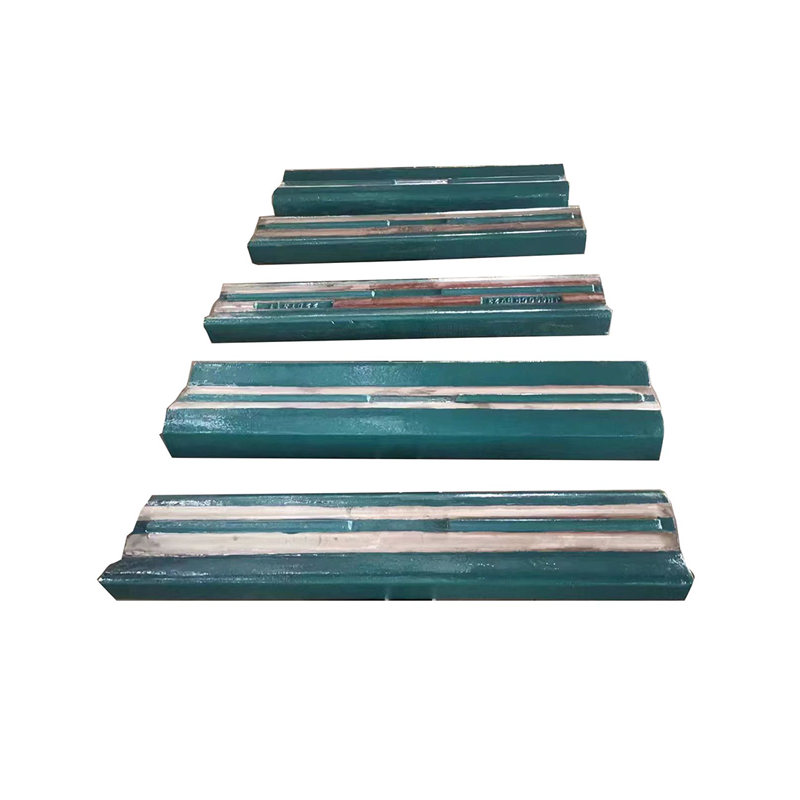

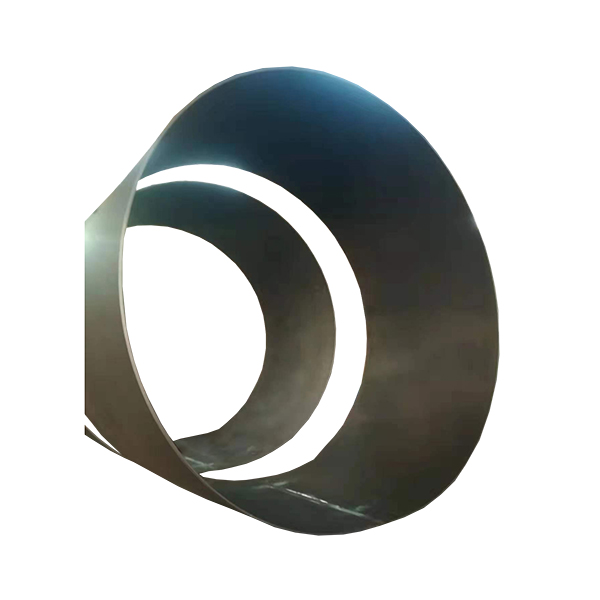

Roller press is an important pre-grinding equipment in building materials industry, which can greatly increase the output of ball mill. Because of its simple structure, stable operation and high efficiency, it is also used by many enterprises as the final grinding. The roller sleeve is the most important part of roller press, its performance directly determines the output and operation rate of roller press. The material of roller sleeve of roller press is 35CrMo forgings + wear-resistant layer, which gives consideration to the hardness and toughness of roller sleeve, and has strong wear resistance. It can be used for grinding limestone, clinker and etc.

a. Advanced manufacturing process:

● Customized design: According to the customer’s situation, there are two kinds of roller sleeves: composite casting and inlay hard alloy nails. By comparison of these two, each has its advantages and disadvantages. Composite casting roller sleeve is more convenient to overlaying welding after it is worn, and it can be offline overlaying welding or online overlaying welding. The service life of inlay hard alloy nails roller sleeve is longer than that of composite casting roller sleeve, but later maintenance is more troublesome, generally choose offline overlaying welding.

● Manufacturing process: The composite casting roller sleeve adopts more advanced centrifugal casting technology, which greatly improves the casting quality. The casting nail adopts a specially designed staggered arrangement, which can keep the wear speed in the middle part and end part consistent and improve the utilization rate of the roller sleeve.

● Quality Control: Strictly control the process in the production process, and take spectral analysis on the material to ensure the quality of the product.

b. Strict inspection:

● Flaw detection should be performed for each product to ensure that there are no air holes, sand holes, slag inclusions, cracks, deformation and other manufacturing defects.

● Each product is inspected prior to delivery, including material tests and physical performance tests to ensure functional performance and provide laboratory test sheets.

Performance index

Hardness: 60HRC-65HRC

Application

It is widely used in the roller press of power, building materials, metallurgy, mining and other industries.

Product detail pictures:

Related Product Guide:

No matter new shopper or old customer, We believe in very long expression and dependable relationship for Hot Sale for Ball Mill Feed Silo - Roller sleeve of roller press – Fiars , The product will supply to all over the world, such as: Egypt, Mecca, Madagascar, With the development and enlargement of mass clients abroad, now we have set up cooperative relationships with many major brands. We have our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the "quality first, customer first, We are provideing high-quality, low-cost products and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!