In recent years, with the warming of the cement industry market and the gradual improvement of national environmental protection requirements, various cement enterprises have paid more and more attention to environmental sanitation. Many cement companies have put forward the slogan of building a "garden-style cement factory", and investment in environmental protection transformation has been increasing.

The most dusty place of cement factory is the limestone yard. Due to the high distance between the long arm of the stacker and the ground, and the relatively dry limestone, the stacker raises ash easily during stacking process. Many of the limestone yards were originally open, but they were later enclosed with greenhouses, which can reduce the pollution to the environment to some extent. however, it is extremely unfavorable to the health of the staff and the smooth operation of the equipment with so much dust in a confined space.

Powerful tool to contain dust

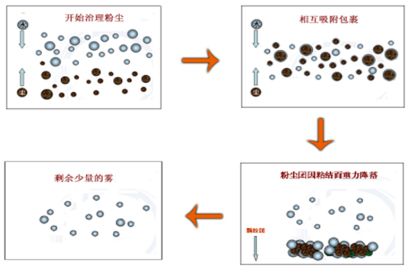

Independently developed by Tianjin Fiars intelligent technology Co, Ltd., the dry fog dust suppression system can completely solve the problem of heavy ash in the limestone yard (coal yard, auxiliary material yard). Its principle is to generate a large amount of dry mist through the atomizing nozzle, and spray it to cover the place where the dust is generated. When the dust particles contact the dry mist, they will stick to each other, agglomerate and increase, and finally sink under their own gravity to achieve the purpose of eliminating dust.

The dry fog and dust suppression of the stacker is to install a certain number of nozzles at the long arm of the stacker. The dry fog generated by the nozzles can completely cover the blanking point, so that the dust cannot be raised, thus completely solving the problem of the yard. The dust problem not only ensures the health of the post personnel, but also increases the service life of the equipment and spare parts.

Professional support

The dry fog dust suppression system developed by Tianjin Fiars is a mature and reliable system. In 2019, it has applied for two invention patents for the rotary liquid ejector and the dust removal system for the stacker and the dry fog dust suppression device for the belt conveyor, and owns the copyright of the dust suppressor control system software. In addition to the raw material storage yard, this system can also be used in road spraying, equipment spraying, etc. It has solved the problem of heavy ash for more than 20 cement plants such as BBMG and Nanfang Cement, and has been well accepted by our customers.

Post time: Jan-16-2022