Fu series chain conveyor is a kind of continuous conveying equipment used in the conveying of powdery and small granular materials. It is generally used for conveying materials horizontally (or inclination angle ≤ 15° ) , and has the characteristics of reliable performance, economical and practical. This product has the characteristics of reasonable design, advanced structure, low energy consumption, long service life, stable and reliable operation, energy saving and high efficiency, good sealing, safe use and convenient maintenance. It is widely used in building materials, construction, chemical industry, thermal power, grain processing, mining, machinery, metallurgy, transportation, ports and transport and other industries. The advanced conveying principle , together with sophisticated design and manufacturing process provide a reliable guarantee for the excellent performance of this series of products.

I. Working principle

The superiority of FU chain conveyor comes from its working principle. Because the material has the characteristics of internal friction and side pressure , the movement of the conveyor chain increases the internal pressure of the material in the machine tank and the internal friction between the particles. When the internal friction between the material layers is greater than the external friction between the material and the trough wall, the material will flow forward together with the conveyor chain like water. When the ratio of the height of the material layer to the width of the machine trough meets certain conditions, a stable material flow can be formed.

II. Main features

1. Large conveying capacity. Efficient conveyors allow large volumes of material to be conveyed in a small volume space. The maximum conveying capacity can reach 500 m 3 / h .

2. Low energy consumption for transportation. With the help of the internal friction of the material, the pushing material is changed into a pulling material.

3. Good sealing and safety. The fully sealed casing structure enables dust to stay inside the device without leakage. Reduced environmental pollution.

4. Long service life. The conveyor chain is made of alloy steel through advanced heat treatment, which is durable.

5. Flexible process layout. It can be arranged on elevated, ground or pit, and can be horizontal or climbing installation( not more than 15 degree) .It can also be installed horizontally with the same machine, and can also be multi-point feed and discharge.

III. Selection of chain speed

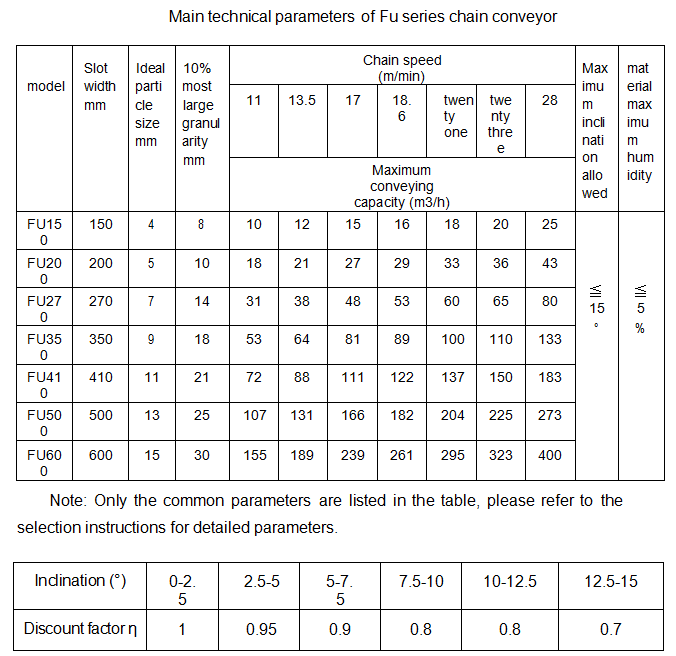

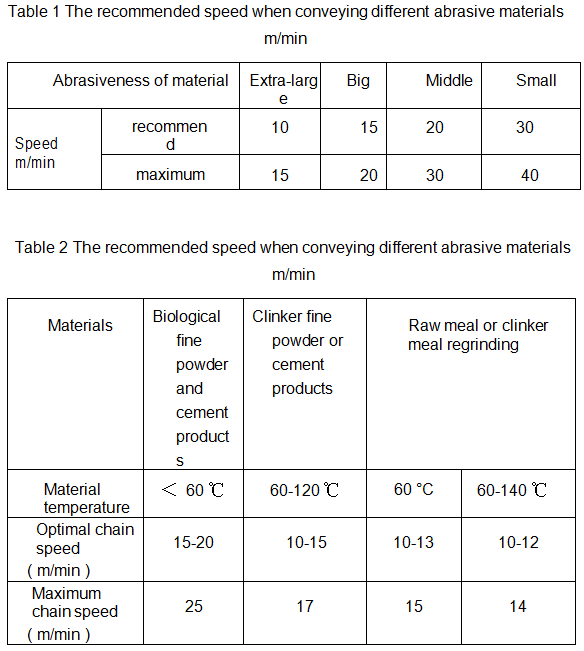

The user should first select the appropriate chain speed according to the state of the material. Generally, the material with strong abrasiveness, material with high temperature, material with a large proportion of coarse particles and large particles should choose a slow speed. Materials with little abrasiveness, such as coal powder can choose fast speed( see table 1 , table 2 )

IV. Specification parameter table

The specifications of FU chain conveyors are listed in the following table. The range of conveying capacity of each model at different chain speeds is listed in the table. The same conveying capacity can be selected from the table to different models. If a larger model is selected, the chain speed can be reduced and the wear is small; if a smaller model is selected, the chain speed is faster and the wear is relatively high. It should be noted that when the actual conveying volume is less than 30% of the conveying capacity of the machine, the thin material layer in the groove will cause the conveyor chain to idle, which will also increase the wear and tear of the equipment.

V. Selection and process layout

The length of the intermediate section depends on the design requirements. In the process layout, several standard intermediate sections and several non-standard intermediate sections can be combined to form the required length L. The standard section combination is used as much as possible. There are 2 kinds of conveyor chains: common type ≤110℃ and heat-resistant type. If the material temperature is higher than 110℃, please contact our factory for special order and adopt heat-resistant design.

Conveyors mainly include:

1. Transmission device

2. Head section device

3. Tail joint device

4. Intermediate standard section, intermediate non-standard section

5. Operation part

VI. Main Parts

Post time: Jun-02-2023