I. System characteristics

- a. The process of the pre-feeding and metering device in the system is airtight, and the discharge channel of the airflow is considered.The pre-feeder adopts a rotary type, multi-compartment, with mixing, and multi-layer structure, which can effectively eliminate the impact of the warehouse pressure and prevent the material from being flushed. The mixing device can prevent the powder material from bridging and clogging, so that the material is always in a loose state and maintains a certain density; The multi-compartment structure ensures uniform feeding and good controllability. The amount of the feeding can be realized by changing the motor speed through the main frequency conversion speed regulation, and it is adjusted synchronously with the rotor scale.

- b. ZZC rotor weighing feeder adopts sealed self-aligning bearing support, spoke rotor, high sensitivity, material free fall working mode, frequency conversion speed regulation, pulse speed measurement, good sealing performance, uniform feeding, no punching, the measurement accuracy is better than ±0.5%.

- c. The rotor scale directly measures the weight of the powder material in the rotor, which is actually a force.Therefore, the fluctuation of materials or the change of filling rate can be measured during the rotor rotation, and can be corrected before feeding the process line, so both short-term accuracy and long-term accuracy are high.

- d. The discharge port adopts a flexible connection and is on the same axis as the drive shaft of the rotor scale, so the force generated by the material in and out and the positive pressure air flow are perpendicular to the guide shaft, and no torque will be generated on the rotation shaft. To maintain the force measurement not be affected. Therefore, it has strong anti-interference ability and is less affected by external factors, which is conducive to improving the measurement accuracy.

- e. The flow can be changed within the range of 1:10, and the flow adjustment range is wide. The signal output by the load cell is stable when the flow rate changes, which is conducive to improving the measurement accuracy, so it can still achieve high measurement accuracy under the condition of small flow rate.

- f. The installation form of the system can be directly hung on the bottom of the silo, or can be installed on the ground, which is convenient and flexible.

- g. The PLC control system can realize automatic measurement, quantitative feeding, fault alarm, instantaneous flow and cumulative flow display, and has perfect signal transmission and communication functions.

II. Parameter configuration

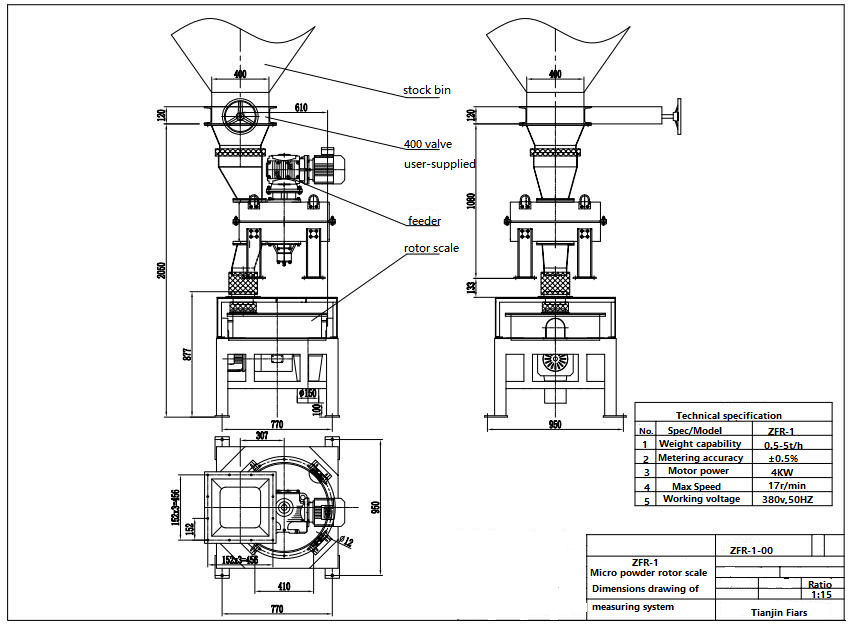

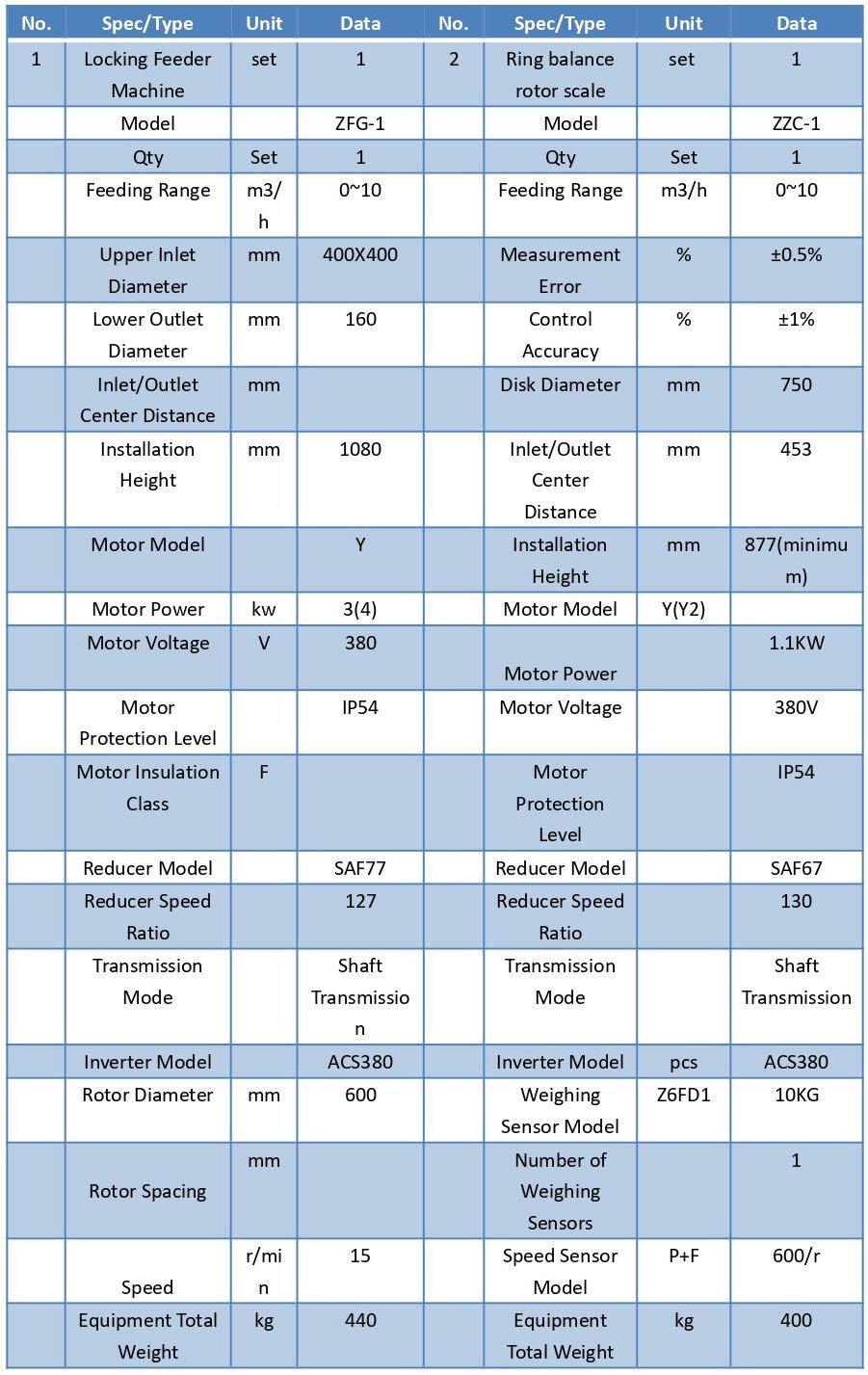

ZFR-1 Parameter configuration

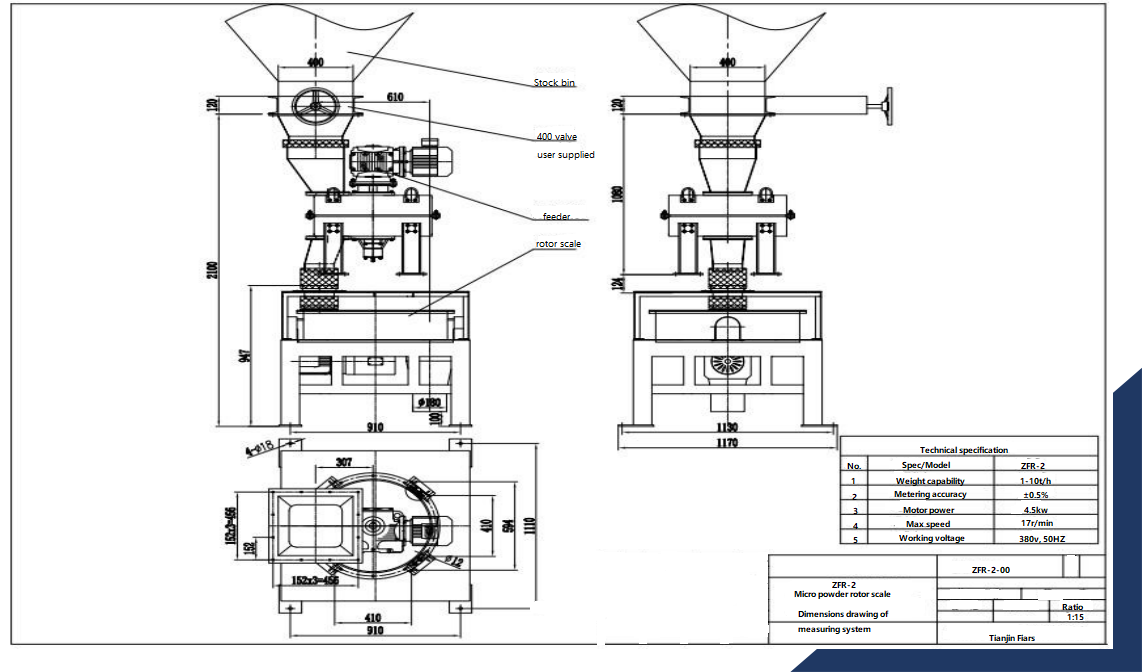

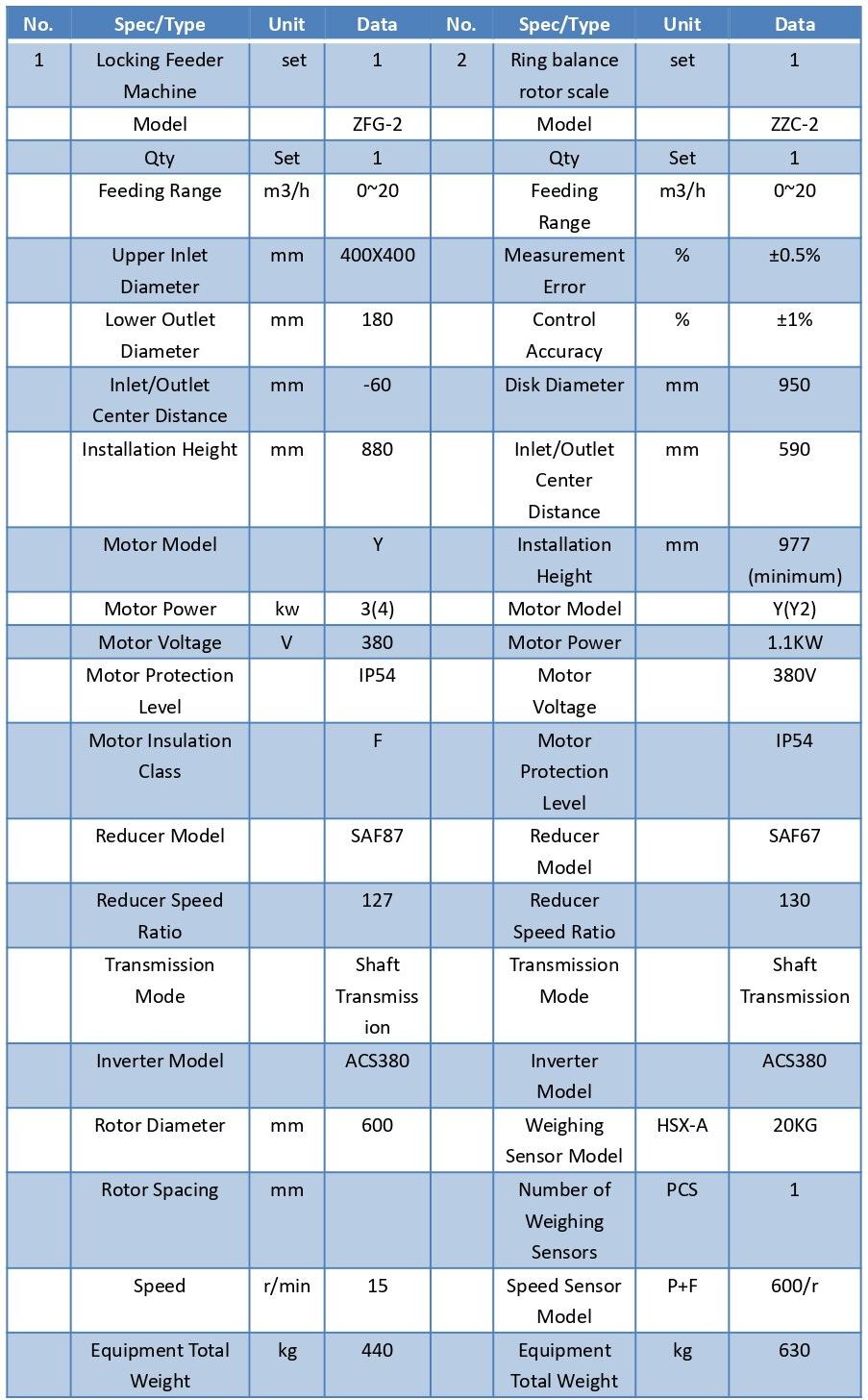

ZFR-2 Parameter configuration

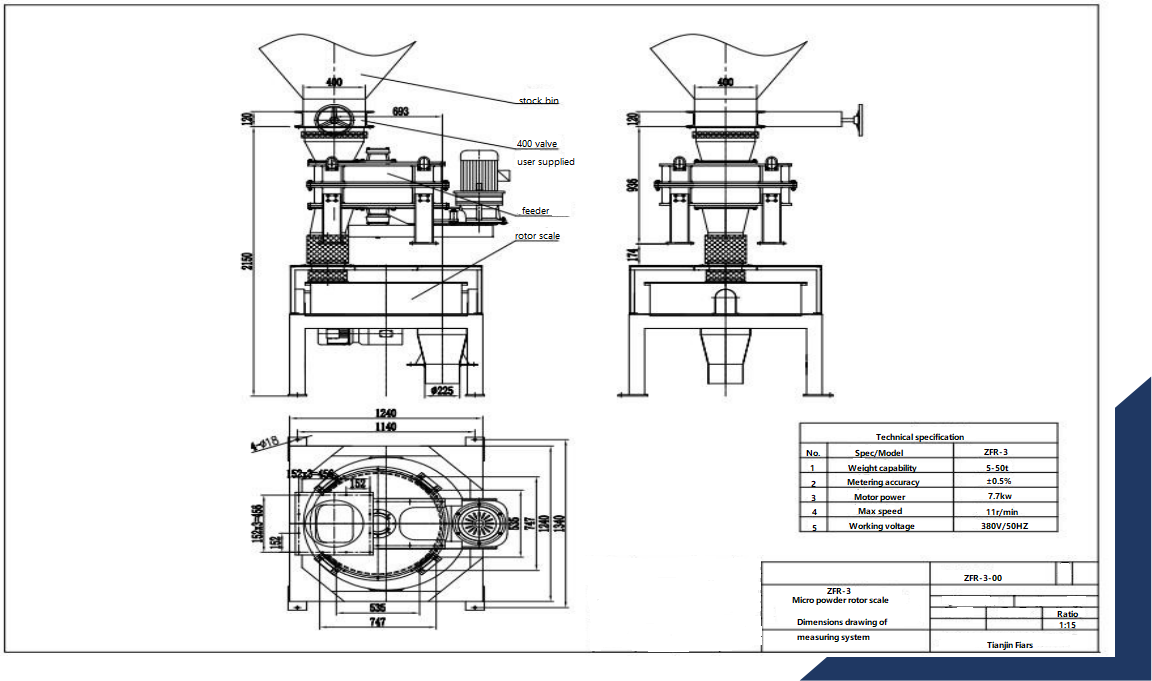

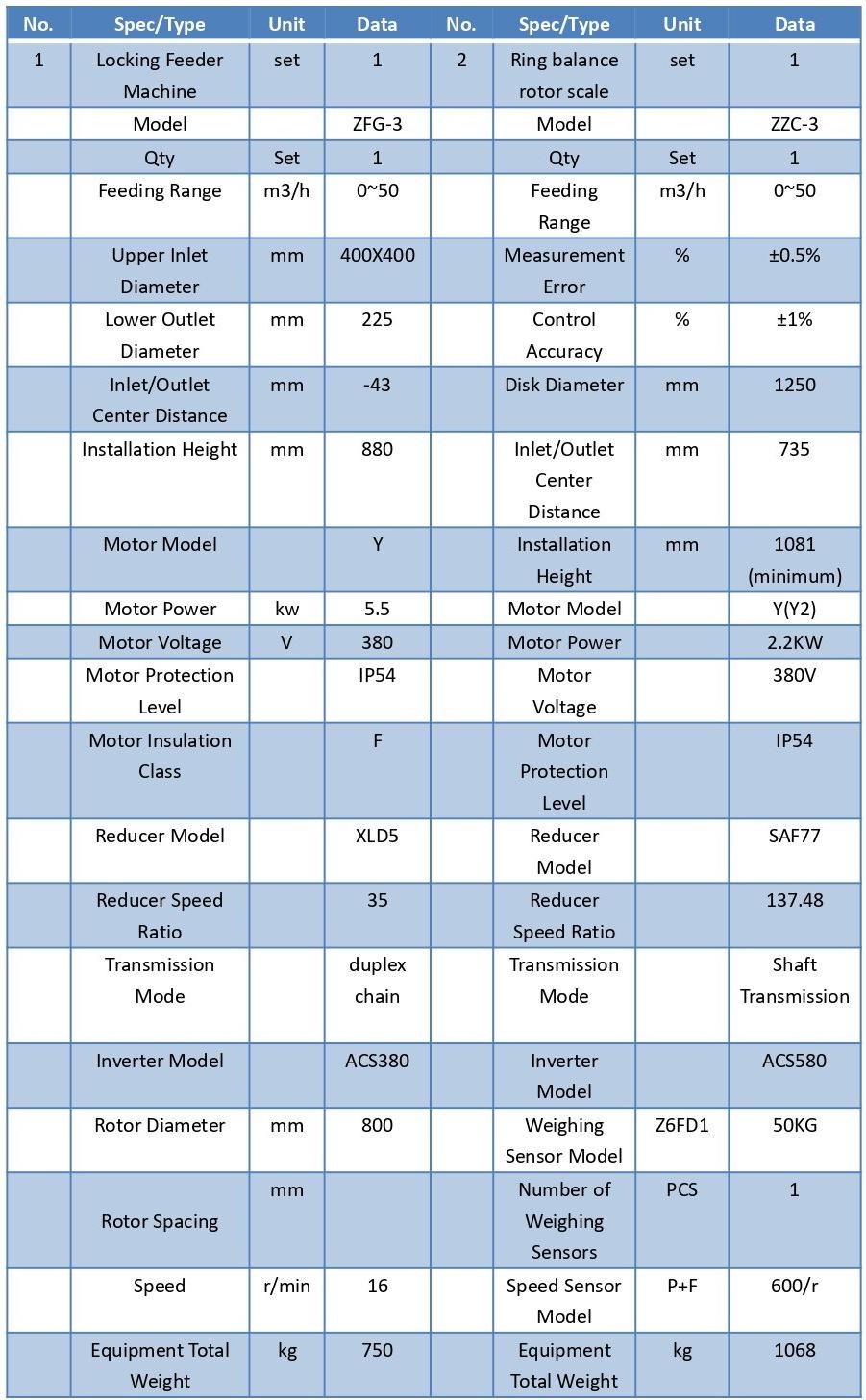

ZFR-3 Parameter configuration

ZFR-4 Parameter configuration

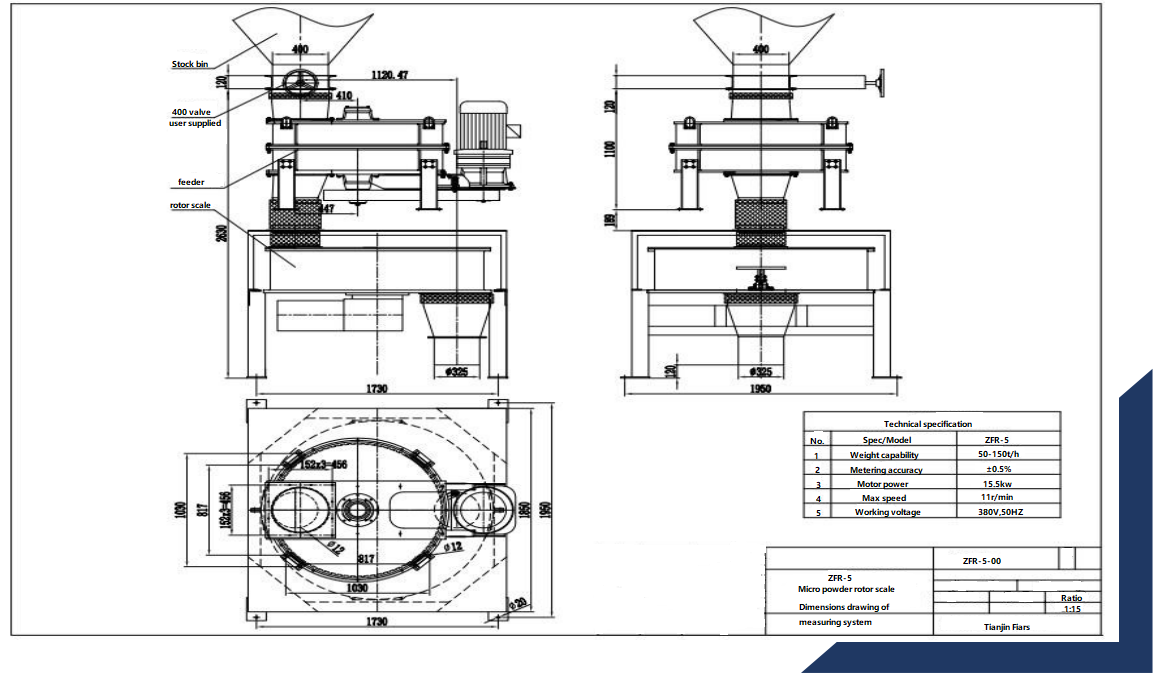

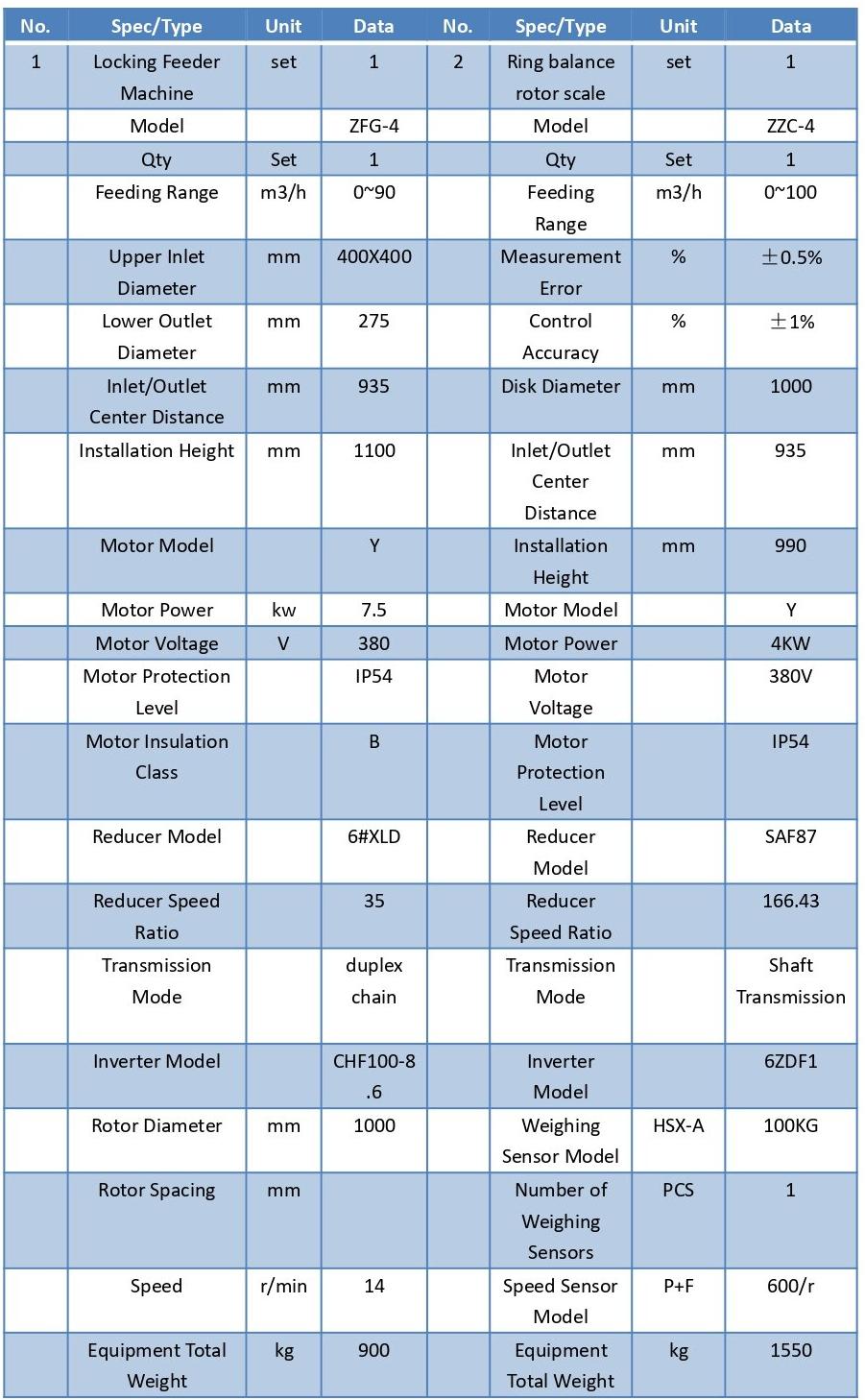

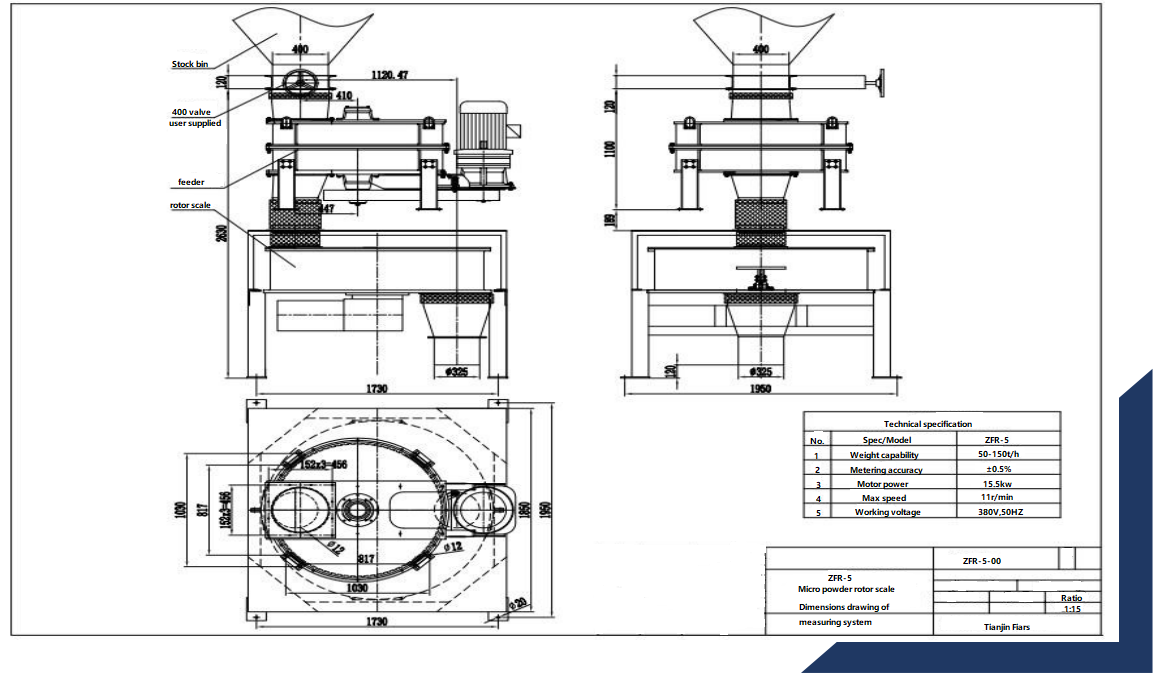

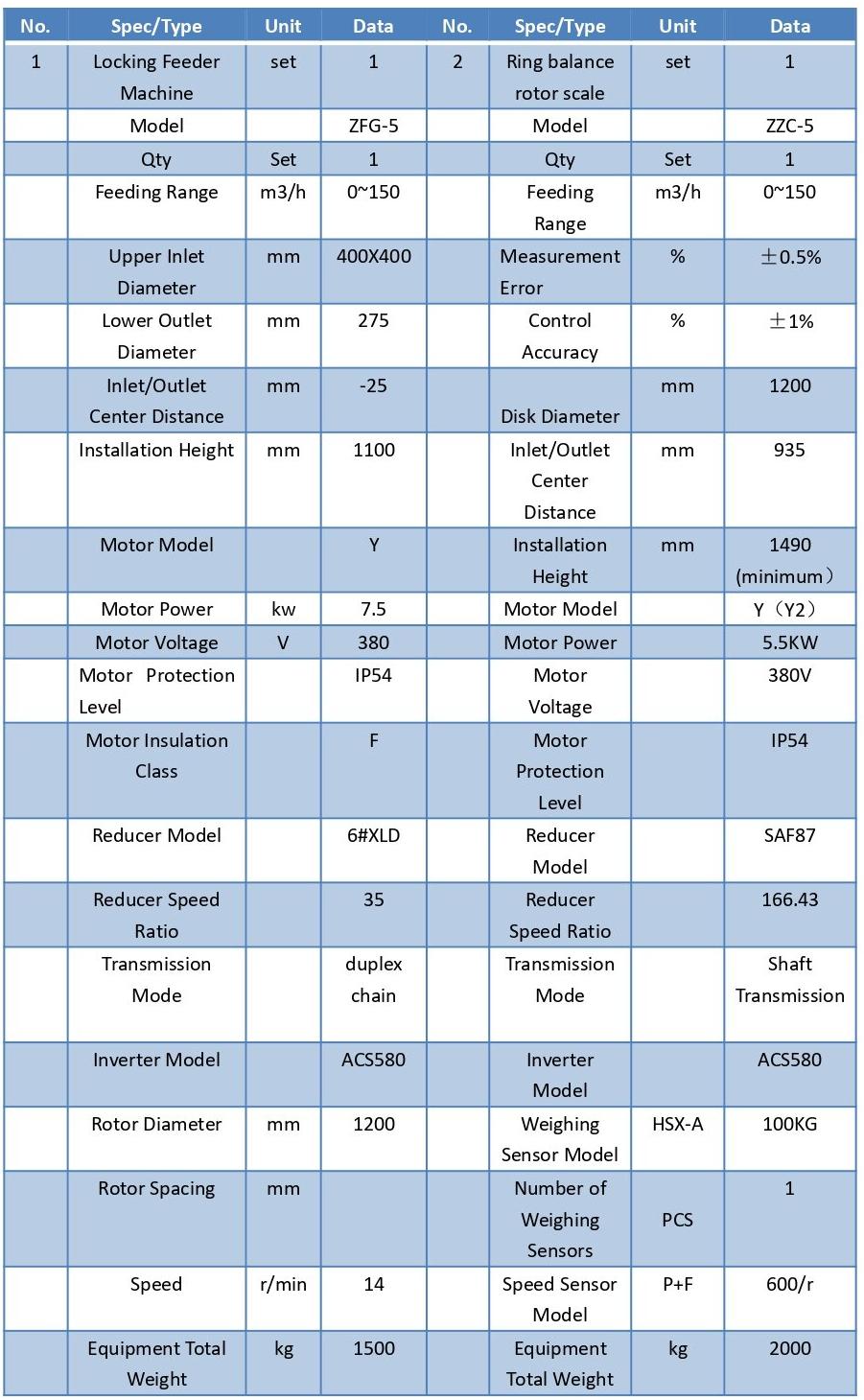

ZFR-5 Parameter configuration

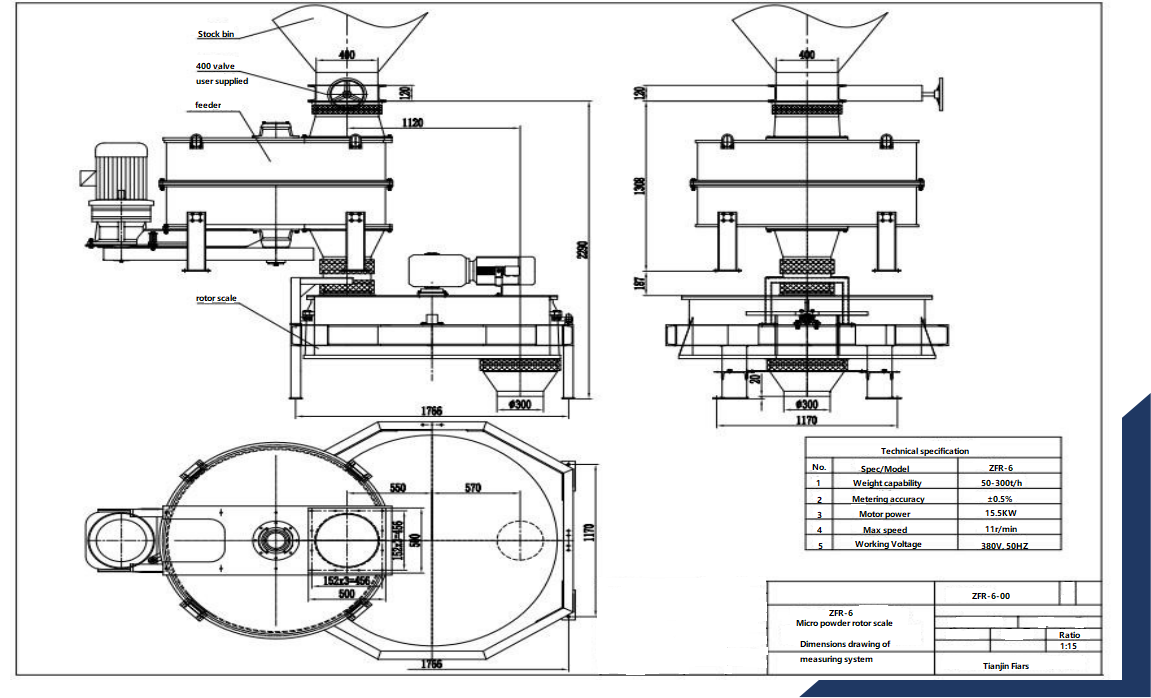

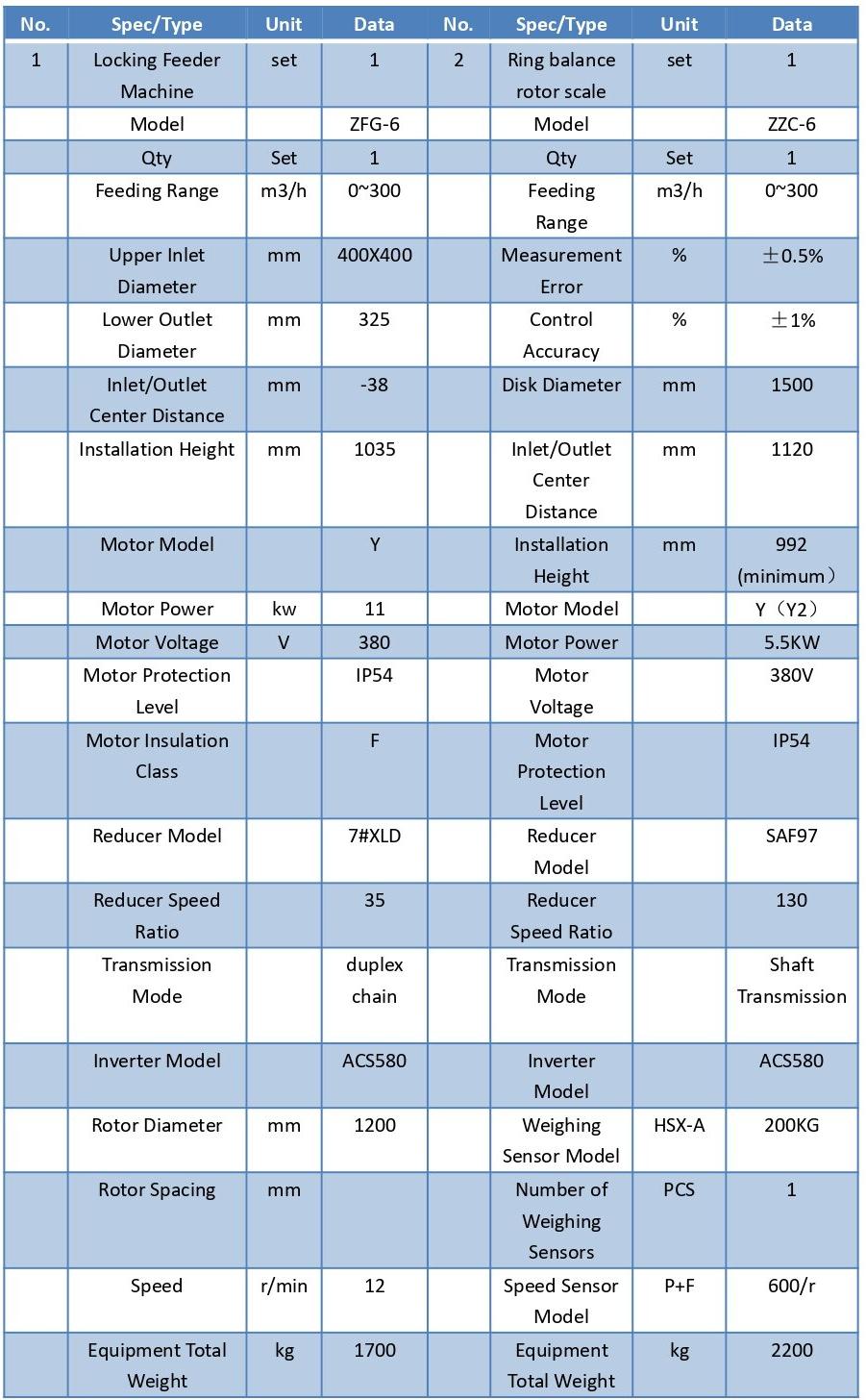

ZFR-6 Parameter configuration

Post time: Mar-31-2023