In the production process, dust pollution is usually caused during pilling, transferring and loading of material. Especially, when the weather is dry and windy, the dust pollution will not only pollute the environment of factory but also do a lot of harm to employees’ health. Usually, the dust points are numerous and widely distributed. Besides, the type, granularity, temperature, humidity and causes of dust do vary, which makes dust pollution hard to govern.

In order to solve the ungovernable dust problem for cement plant, our company captures ultrafine dust with fine water-spray generated by ultrasonic wave by using micron dry fog dust-cleaning device. This solution can control dust at the very beginning point so that dust will be controlled effectively. In the end, this solution can not only ensure dust governance performance, but also ensure the cleanness of the production line.

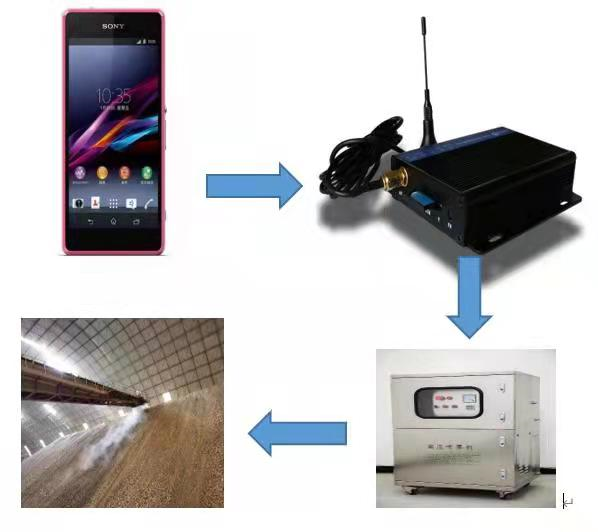

Our company’s intelligent drying/spraying system (version 2.0 upgrade) adopts the Internet technology and integrates mobile phone apps to realize remote synchronous control function. By downloading the mobile phone app, the 5G DTU network can be used (the data transmission unit DTU is specially used for serial data conversion. It is a wireless terminal device that transmits IP data or converts IP data to serial port data through a wireless communication network, and is the core of remote control)

The 5G communication module establishes reliable wireless communication with the all-in-one computer, and the mobile APP control interface is completely consistent with the touch screen control interface and can be controlled synchronously and effectively. The system supports the simultaneous networking of two mobile phones, which fully realizes the local and remote wireless control of the drying/spraying system, and maximizes the convenience of customer application.

Post time: Mar-18-2022