I. Working principle

The motor drives the grinding disc to rotate through the reducer. The material falls from the discharge port to the center of the grinding disc, moves to the edge of the grinding disc under the action of centrifugal force and is rolled by the grinding roller. The high-speed upward hot air flow is brought to the high-efficiency powder separator integrated with the vertical mill. After being sorted by the separator, the coarse powder is returned to the grinding table for re-grinding,and then the product is collected in the dust device. The coarse-grained materials that are not carried by the hot air flow and the metal parts that enter accidentally fall from the air ring, and after being scraped out by the scraper, they are fed into the mill by the external circulation bucket elevator for grinding again.

II FAQ

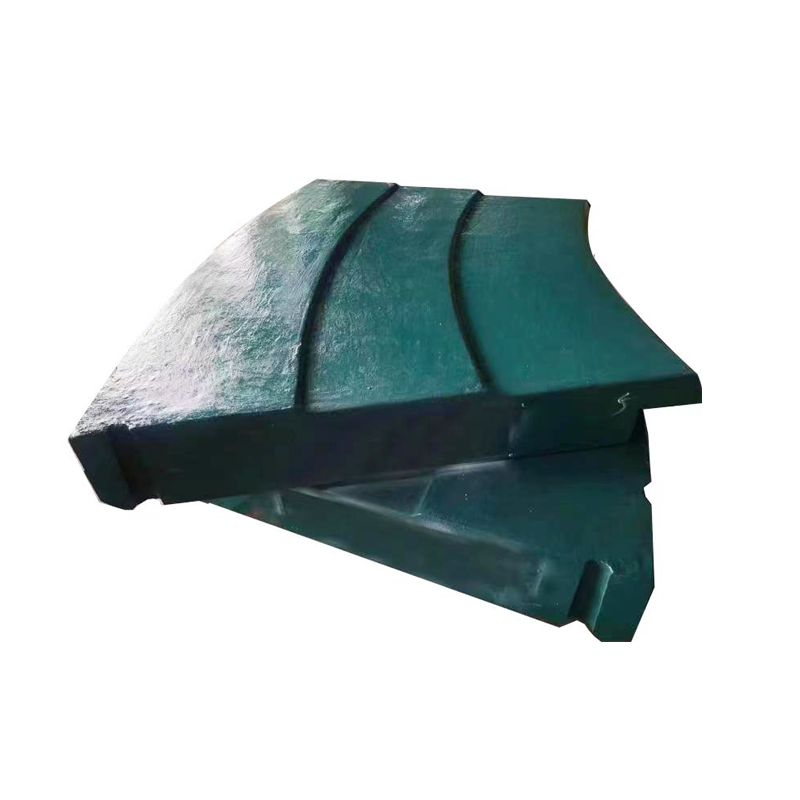

1. Wear and repair of vertical grinding rollers and grinding disc linings

During the use of the vertical grinding roller body and the wear-resistant lining plate, once there is a matching gap, the wear between the body and the lining plate will increase, and the hot air and cement particles will continue to scour the matching surface, resulting in the generation of grooves. As a result, there is an impact collision between the body and the lining plate, and in severe cases, the lining plate is cracked or even broken, and the machine is damaged, especially the damage of the reducer, resulting in malignant events.

Once such a problem occurs, the general repair method is difficult to solve, and the replacement cost is high.

2. Wear and repair of bearing chamber of vertical grinding roller

The assembly requirements of vertical grinding roller bearings are relatively strict, and enterprises generally use the method of cooling the bearings in dry ice. Once there is a gap between the bearing and the bearing chamber, it will affect the normal operation of the bearing, cause the bearing to heat up, and cause the bearing to burn in severe cases.

3. Leakage treatment of vertical mill reducer

The leakage of the vertical mill reducer not only affects the appearance of the machine, but also wastes oil, causing great trouble to the maintenance of the equipment.

Post time: May-27-2022