OEM Factory for Rotary Kiln Hydraulic Thrust Roller - Cement mill preheater flap valve – Fiars

OEM Factory for Rotary Kiln Hydraulic Thrust Roller - Cement mill preheater flap valve – Fiars Detail:

Technical Characteristics

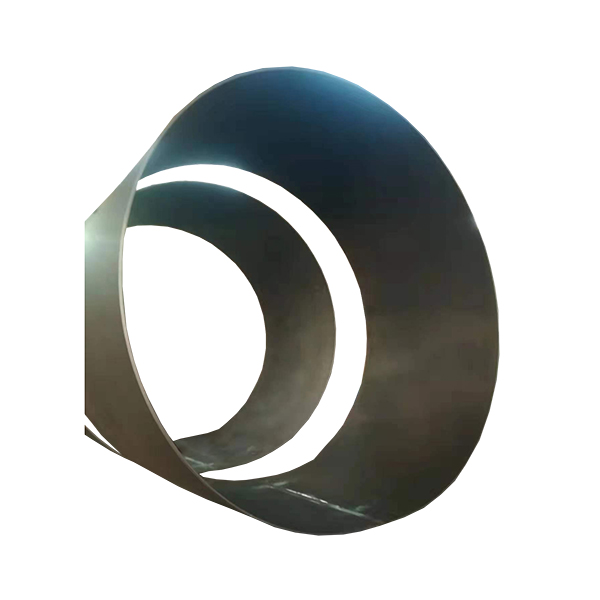

In cement production line system, the preheater is an important part and a landmark building of cement production enterprises. It can preheat the raw meal and improve the output of rotary kiln. Preheater flap valve plays an important role in air lock and stable continuous feeding which is a very important link in the preheater system. In the actual operation situation, due to the unreasonable structural design of the flap valve which caused frequent air blow-by, flapping inflexible and ablating phenomenon, seriously affect the stability of the material feeding, the output of the rotary kiln and even the clinker quality will also be affected.

After In order to solve this problem, after the investigation and survey of a number of companies, the modification solution was designed and the parts which easy have faults are optimized which can make the flap valve operation more flexible and better sealing effect.

a. Change the shaft sleeves on both sides to spherical ball bearings to ensure the operation flexibility, the shell is covered with double sealing cushion and coated sealant to ensure the sealing of the shell.

This kind of structure has good sealing performance and can keep the bearing clean, which effectively ensures the flexibility of the flap valve operation and greatly improves the effect of air locking.

b. Independent access door design makes the future inspection and replacement of the valve plate simple and easy, which can shorten the maintenance period and reduce the maintenance cost.

Advantages of Equipment

After modification of the flap valve, the clamping stagnation was completely eliminated, and the valve plate corrosion was effectively contained, achieving the effect of extending the service life and reducing the purchase cost of spare parts.

The successful modification of preheater flap valve not only saves costs and creates great economic benefits, but also creates certain social benefits in terms of energy saving, consumption reduction, efficiency improvement and environmental protection.

Product detail pictures:

Related Product Guide:

Sticking to the belief of "Creating products of high quality and making friends with people from all over the world", we always put the interest of customers in the first place for OEM Factory for Rotary Kiln Hydraulic Thrust Roller - Cement mill preheater flap valve – Fiars , The product will supply to all over the world, such as: Guatemala, Jordan, Maldives, As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers, and establish a long term win-win business relationship. For more information, please contact us. And It is our great pleasure if you like to have a personally meeting in our office.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.