OEM manufacturer Butterfly Valve - Rotary kiln for building materials and metallurgy – Fiars

OEM manufacturer Butterfly Valve - Rotary kiln for building materials and metallurgy – Fiars Detail:

Technical Characteristics

Rotary kiln is the most important equipment in the building materials industry, which can be divided into cement kiln, metallurgy kiln and chemical kiln and lime kiln according to the different materials. Cement kiln is mainly used for calcination of cement clinker, which can be divided into dry cement kiln and wet cement kiln. Metallurgical chemical kiln is mainly used for metallurgical industry, for the steel plant used for magnetic roasting of poor iron ore and oxidation roasting of chromium and nickel ore; for the refractory plant used for roast high aluminum vanadium soil; for the aluminum plant used for roast clinker, aluminum hydroxide; for the chemical plant used for roasted chromium ore and chromium powder and other minerals. Lime kiln is used for calcination of active lime and light burnt dolomite in steel plant and ferroalloy plant. The shell material of rotary kiln is generally 235C, 245R, 20G, etc. The thickness varies from 28mm to 60mm. At present, the largest shell diameter is 6.1m (for the rotary kiln of 10000t/d line).

a. Advanced manufacturing process:

● Customized design:Various shell of diameter, thickness and length can be made according to the needs of the customer. It can be manufactured in whole or in part.

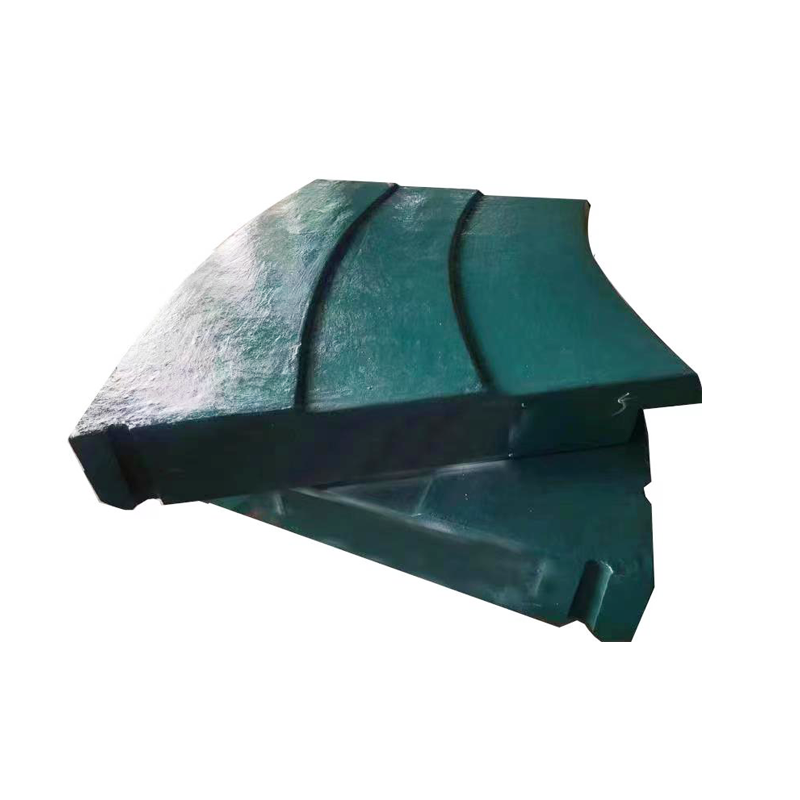

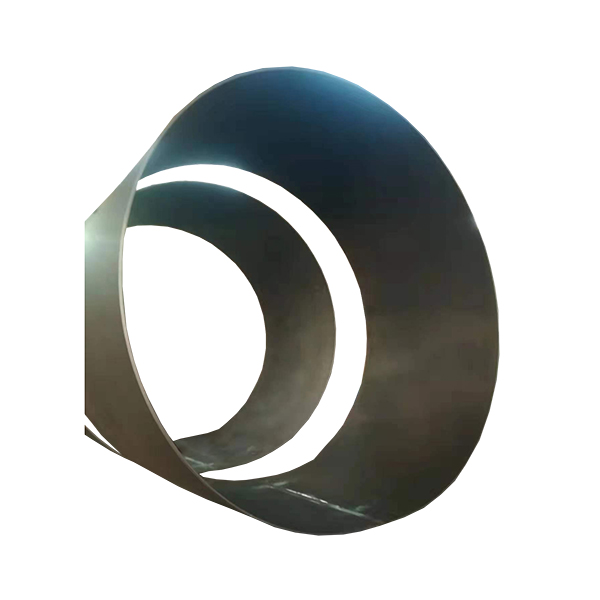

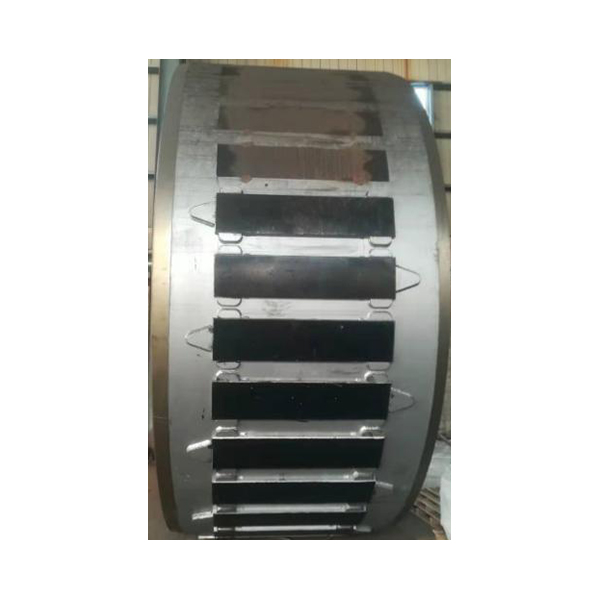

● Manufacturing process: Machining welding groove with edge milling machine; Welding with automatic submerged arc welding, with smooth and beautiful appearance; The interior is supported by Union Jack Flag shape to prevent deformation; With a large rolling machine, the cylinder accuracy is relatively high. The surface is sprayed with anti-corrosion and anti-rust paint.

● Quality Control: Strictly control every step in the production process, strictly check the roundness,parallelism and other indexes to ensure that the tolerance meets the requirements.

b. Strict inspection:

● Welding joint flaw detection should be performed for each product to ensure that there are no air holes, sand holes, slag inclusions, cracks, deformation and other welding defects.

● Each product is measured in axial and radial directions to ensure dimensional tolerances meet industry manufacturing standards.

Performance index

Not lower than the industry standards.

Application

It is widely used in the rotary kiln of power, building materials and metallurgy industry.

Product detail pictures:

Related Product Guide:

Our growth depends on the superior equipment ,exceptional talents and continuously strengthened technology forces for OEM manufacturer Butterfly Valve - Rotary kiln for building materials and metallurgy – Fiars , The product will supply to all over the world, such as: Pakistan, UK, San Diego, Since its foundation , the company keeps living up to the belief of "honest selling , best quality , people-orientation and benefits to customers. " We're doing everything to supply our customers with best services and best solutions . We promise that we are going to be responsible all the way to the end once our services begin.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.