Reliable Supplier Bin/Fine Coal Bin - Vertical grinding roller sleeve – Fiars

Reliable Supplier Bin/Fine Coal Bin - Vertical grinding roller sleeve – Fiars Detail:

Technical Characteristics

a.Type and Material:

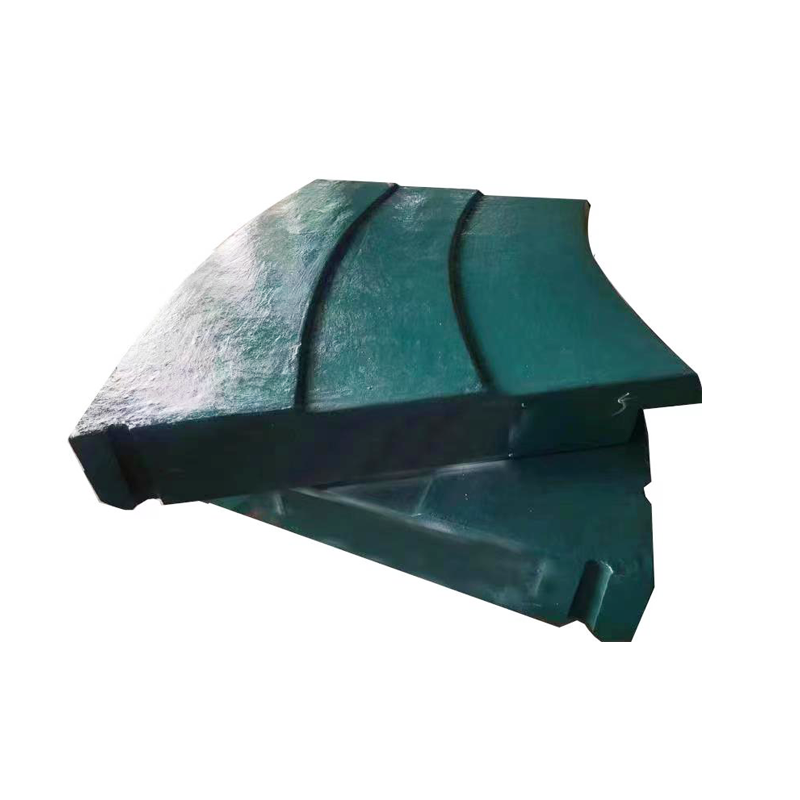

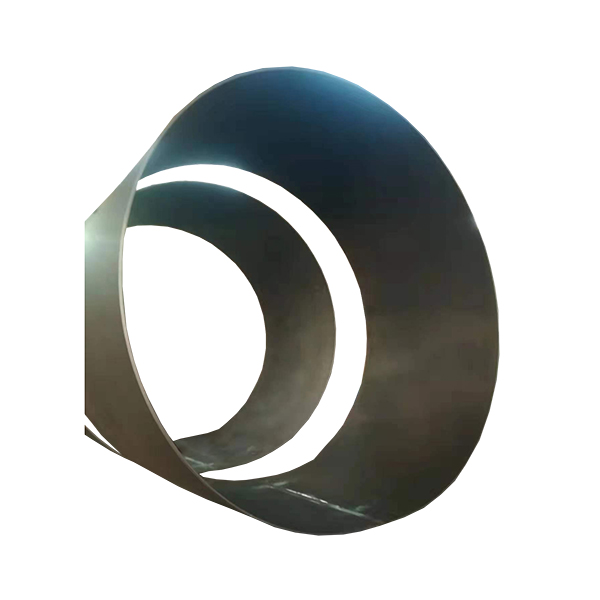

The shape of vertical grinding roller sleeve has two types: tire roller and conical roller, the material is high chromium cast iron, with strong hardness and wear resistance which can be used for the grinding of limestone, pulverized coal, cement and others.

b. Advanced manufacturing process:

● Customized design: Sand casting, can be cast according to the user drawings.

● Manufacturing process: The heat treatment process is controlled by the computer program, the fitting surface is fine turning by the CNC lathe.

● Quality Control: Smelting steel water shall be discharged after qualified spectral analysis; the test block for every furnace shall be heat treatment analysis, and the next process shall proceed after the test block is qualified.

c. Strict inspection:

● Flaw detection should be performed for each product to ensure that there are no air holes, sand holes, slag inclusions, cracks, deformation and other manufacturing defects.

● Each product is inspected prior to delivery, including material tests and physical performance tests to ensure functional performance and provide laboratory test sheets.

Performance index

Material hardness, impact resistance: hardness 55HRC-60HRC;

Impact toughness Aa≥ 60j /cm².

Application

It is widely used in the vertical mill of power, building materials and metallurgy industry.

Product detail pictures:

Related Product Guide:

We have our own sales team, design team, technical team, QC team and package team. We have strict quality control procedures for each process. Also, all of our workers are experienced in printing field for Reliable Supplier Bin/Fine Coal Bin - Vertical grinding roller sleeve – Fiars , The product will supply to all over the world, such as: Victoria, British, Croatia, Our main objectives are to provide our customers worldwide with good quality, competitive price, satisfied delivery and excellent services. Customer satisfaction is our main goal. We welcome you to visit our showroom and office. We are looking forward to establish business relation with you.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.