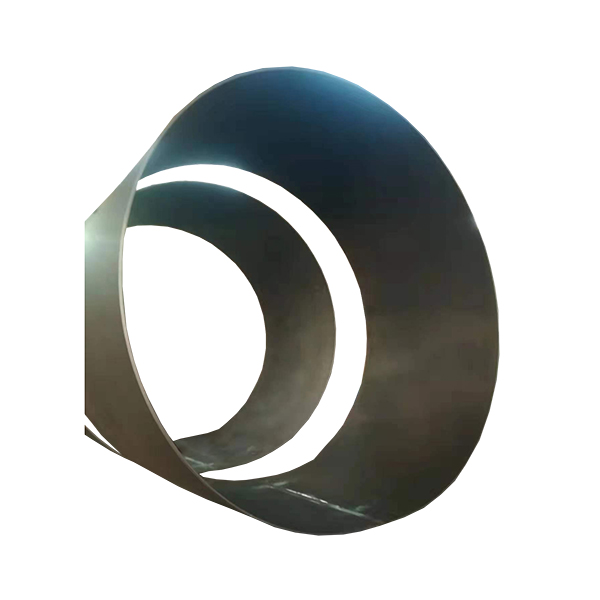

Roller Sleeve Of Roller Press - Processing parts – Fiars

Roller Sleeve Of Roller Press - Processing parts – Fiars Detail:

Technical features

a. With strong comprehensive processing capabilities, we have large processing workshops and skilled workers, and strict inspection standards are customized. There are large vertical lathes, gantry milling, gantry planers, wire cutting machines, automatic welding machines, plate rolling machines, Boring machines, various CNC lathes, machining centers and other advanced processing equipment can process and customize spare parts of various shapes and materials according to customer needs, such as rotary kiln belts and backing plates, large ring gears, retaining wheels, supporting wheels, supporting wheels Wheel tile, kiln head and kiln tail seal, tube mill sliding shoe, hollow shaft, powder separator blade, vertical mill retaining ring, etc. can be processed and manufactured.

b. Advanced manufacturing process:

1) There are various types of turning, drilling, milling, planing, boring and other equipment, which can meet the processing of large, medium and small parts, the maximum processing diameter can reach 10 meters, and the surface roughness can reach 1.6. With mature manufacturing technology and process, it can guarantee the quality and processing period of spare parts.

2) Each process has strict production standards and has a very high yield, which ensures low production costs and short processing period for spare parts.

c. Strict inspection:

We have complete laboratory and testing equipment, and conducts spectral inspection of incoming raw materials to ensure that the material components meet the standards. And each product is subject to strict warehousing and ex-factory inspection, including size, material, etc., and performance testing can be carried out if there are special requirements to ensure that each component can meet the customer’s use requirements.

Performance indicators

Not lower than the national standard or industry standard.

Application

It is widely used in the processing and production of various parts and components of machinery and equipment in the building materials, metallurgy, mining, petroleum, chemical and other industries.

Product detail pictures:

Related Product Guide:

continue on to further improve, to make sure product top quality in line with market and consumer standard requirements. Our firm has a excellent assurance program have already been established for Roller Sleeve Of Roller Press - Processing parts – Fiars , The product will supply to all over the world, such as: Germany, Liberia, Somalia, Selling our products and solutions causes no risks and brings high returns to your company instead. It is our consistent pursuit to create value for clients. Our company is looking for agents sincerely. What are you waiting for? Come and join us. Now or never.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.